Humidity Happens

How It Affects Everything from Customers to HVAC Equipment

When it comes to managing climate in commercial spaces, temperature tends to steal the spotlight. But behind the scenes, humidity control plays a major role in how your facilities feel, function, and operate—especially when managing multiple retail stores, bank branches, clinics, or other commercial chain locations. And here’s the thing: most commercial HVAC systems don’t automatically take care of humidity. That misunderstanding can lead to uncomfortable customers, product loss, indoor air quality issues, and even shortened HVAC equipment lifespan.

Whether you’ve got years in facilities management or you’re newer to HVAC systems, this article breaks down why humidity matters—and how it impacts more than you might think.

What Is Humidity Control—and Why Should You Care?

Humidity refers to the amount of moisture in the air. In commercial environments, the ideal indoor relative humidity (RH) typically falls between 30% and 60%12. When humidity levels drift outside this range—especially for extended periods—it can cause a variety of problems.

While most HVAC systems remove some humidity during cooling, they’re not always designed to maintain consistent indoor RH. Indeed, a common misconception in commercial facility management is that if the HVAC system is working, humidity must be under control too. But that’s not always the case. Most standard commercial HVAC systems—especially packaged rooftop units (RTUs)—are primarily designed to control temperature, not humidity. They remove some moisture as a byproduct of cooling, but this isn't the same as true humidity management. In fact:

- In high-humidity climates, systems often can’t remove enough moisture, especially during mild days when cooling isn’t running at full capacity.

- In dry climates or heated spaces, there’s often no built-in humidification at all.

- In multi-site chains, inconsistencies between equipment types, building envelopes, and regional climates can cause one location to struggle with humidity while another is just fine—even with the same thermostat setting.

So how can you tell if humidity is becoming a problem?

Signs Your Facility Might Need Better Humidity Control:

- Comfort complaints even when the thermostat is set correctly

- Musty smells or visible condensation on windows, vents, or displays

- Mold growth or persistent dampness

- Increased frequency of service calls for “hot/cold” issues that aren’t resolved

- Visible corrosion, water streaks near ductwork, or sweating on metal surfaces

Solutions Worth Considering:

- If these signs are familiar, your HVAC vendor may recommend:

- Adding standalone or ducted dehumidifiers

- Integrating reheat coils or hot gas reheat for better dehumidification

- Upgrading your controls to include RH sensors

- Incorporating energy recovery ventilators (ERVs) to improve indoor moisture balance

Humidity isn’t just a summer issue—it can creep into shoulder seasons or appear in unexpected places like storage rooms or vestibules. Recognizing what your HVAC system can’t do when it comes to humidity is the first step toward protecting your spaces, your products, and your equipment investment. Let’s break down why this matters by looking at three critical areas every facility manager is responsible for: customer comfort, product quality, and HVAC system longevity.

1. Humidity and the Customer Experience

Imagine walking into a retail store that feels stuffy, damp, and smells a bit musty—or worse, has visible condensation on windows or displays. Or walking into a dry, overly air-conditioned bank lobby in winter that leaves your skin itchy and your throat scratchy. Customers may not understand humidity, but they feel its effects. High humidity can make a space feel warmer than it actually is, while low humidity makes cold air feel harsher. Inconsistent or poor humidity control can lead to:

- Discomfort complaints, even when the thermostat shows the right temperature

- Perceived poor air quality

- Negative brand impressions from sticky, smelly, or stale-feeling environments

In retail, clinics, and financial branches and other chains, the customer experience is part of your brand. Proper humidity management helps protect that.

2. Humidity and Product Quality

Humidity isn’t just about comfort. If your business involves perishable goods, specialty merchandise, or equipment displays, it can be a threat to inventory, finishes, and fixtures:

- Packaging materials can warp or weaken when humidity is high

- Leather goods and electronics are sensitive to moisture and can degrade or short out

- Condensation on glass cases or refrigeration units can create visibility and sanitation concerns

- Dry air can cause shrinkage or cracking in wood, paper goods, or sensitive items

One overlooked area? Odor control. Mold or mildew from excess humidity creates persistent smells that are hard to pinpoint but easy to notice—especially for visitors.

3. Humidity’s Hidden Impact on HVAC Systems

If poor humidity control doesn’t show up in complaints or product damage, it might show up in your repair bills. Here’s what many don’t realize: high humidity accelerates wear and tear on your HVAC system:

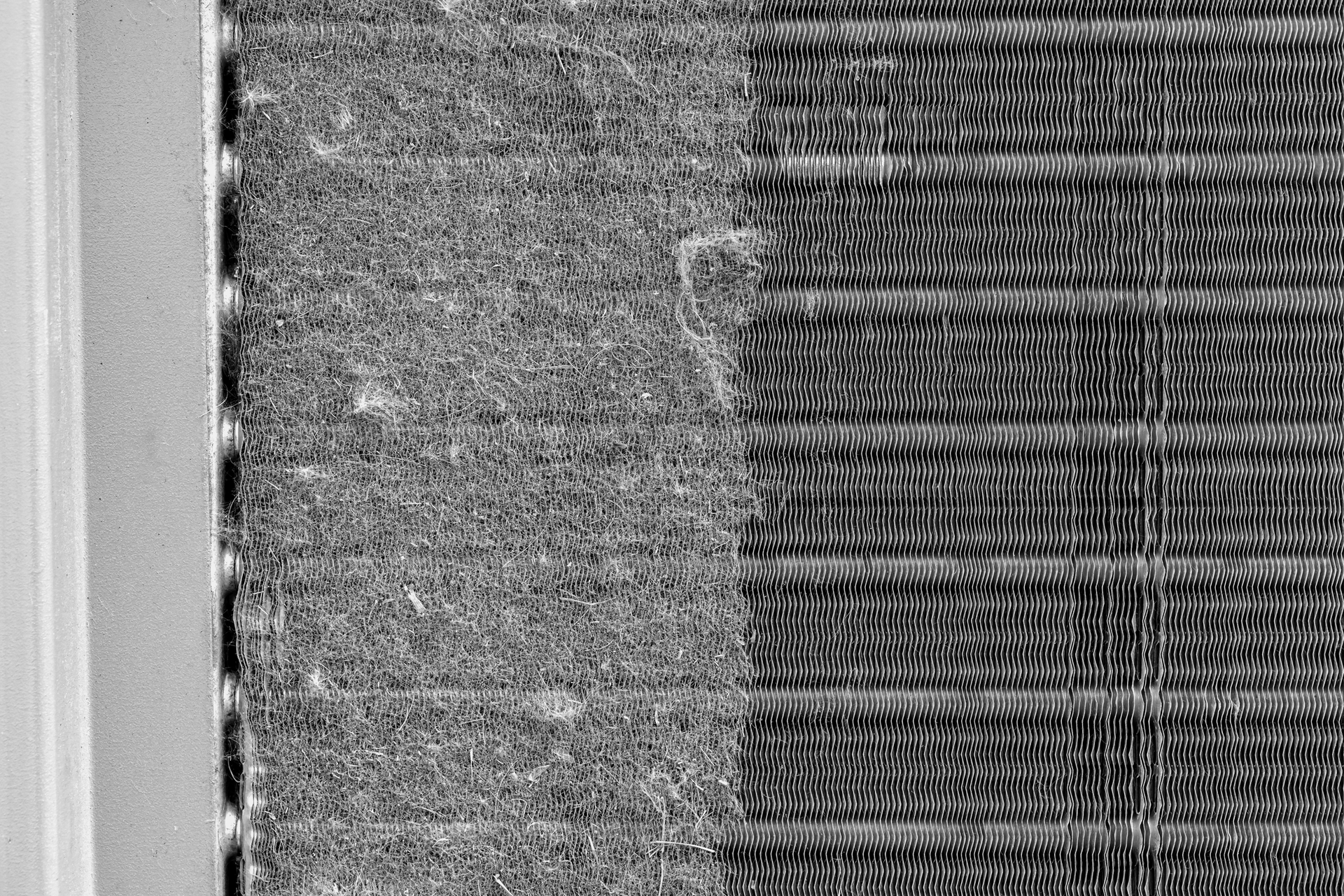

- Corrosion on coils and electrical components due to condensation

- Microbial growth inside ductwork and drain pans, leading to airflow issues

- Increased run time as units work harder to meet temperature setpoints while also removing excess moisture

- Overcooling to compensate for “sticky” air, leading to occupant discomfort and energy waste

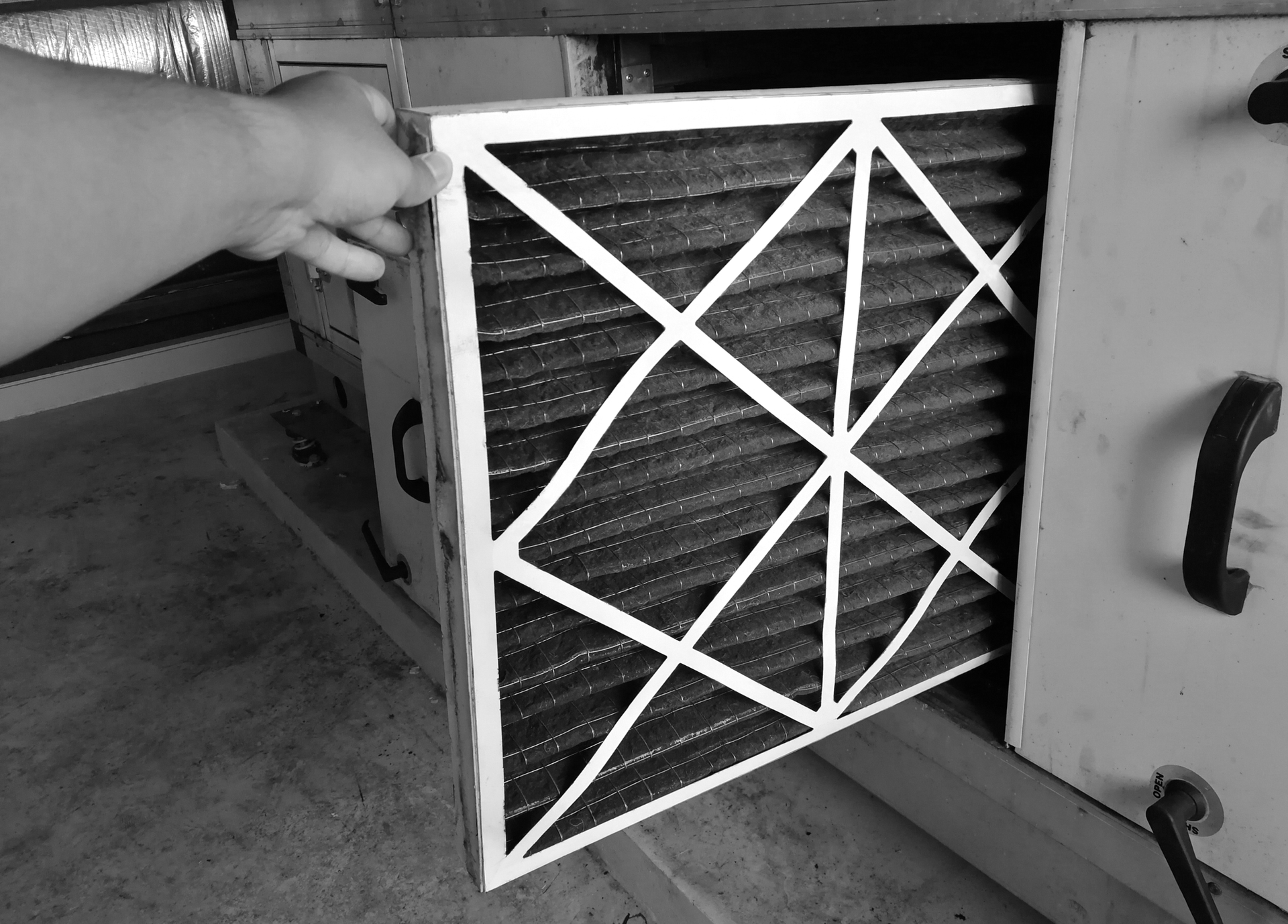

Plus, systems not designed to dehumidify properly may short cycle or experience more frequent part failures—adding cost and shortening lifespan. Humidity also makes it harder for smart thermostats or building management systems to maintain accurate settings, leading to increased service calls or complaints that can’t be resolved by a simple filter change.

What Can Facility Managers Do About It?

Here are a few best practices that can help you manage humidity better across multiple locations:

- Ask your HVAC vendor about humidity monitoring and having it checked during maintenance visits.

- Add humidity sensors or data loggers in problem locations to track trends.

- Consider supplemental dehumidifiers or reheat systems in humidity-prone regions.

- Review seasonal startup/shutdown protocols to ensure your systems adapt to changing humidity loads.

- Educate store or site staff on what humidity-related issues look and feel like.

The Bottom Line

Temperature alone isn’t the whole picture. Humidity plays a critical role in occupant comfort, product protection, and system performance. If your locations are dealing with frequent “temperature” complaints, musty smells, or unexplained HVAC issues, it may be time to look beyond the thermostat. With the right humidity management strategy in place, you’ll see fewer service calls, more predictable equipment costs—and a more consistent experience across your entire portfolio.

To read more about how optimal humidity can improve indoor air quality and extend the life of HVAC systems, check out this FacilitiesDive article: https://www.facilitiesdive.com/news/humidity-control-called-paramount-for-facility-managers/746493/

Sources:

1 EPA Indoor Air Quality https://www.epa.gov/mold/mold-course-chapter-2

2 ASHRAE Standard 55 (Thermal Environmental Conditions for Human Occupancy)

https://www.ashrae.org/file%20library/technical%20resources/standards%20and%20guidelines/standards%20addenda/55_2017_d_20200731.pdf

Have you run into humidity challenges across your locations? Drop a comment below—we’d love to hear how you’ve tackled them, or what questions you have about improving humidity control in your facilities.