Decoding HVAC Ratings

Turning Industry Jargon Into Actionable Insight

Introduction & Purpose

As a commercial facility manager, your primary role is keeping buildings comfortable, efficient, and compliant, while managing dozens or even hundreds of competing priorities. You may outsource HVAC service, maintenance, and installation to trusted vendors, but even so, understanding the basics of HVAC efficiency ratings can give you a significant advantage. These ratings are the language that vendors, engineers, and manufacturers use to describe how much energy a system consumes and how effectively it delivers heating or cooling. By grasping what these acronyms mean - whether it’s SEER2, IEER, or AFUE - you gain the ability to compare proposals with confidence, identify which upgrades will actually save money, and ensure that all your locations align with energy codes and corporate sustainability goals. In short, understanding efficiency ratings isn’t about replacing your vendors’ expertise - it’s about equipping yourself with the knowledge to make better decisions that reduce costs, improve performance, and future-proof your portfolio of facilities.

2. Core HVAC Efficiency Ratings

Below are the frequently encountered ratings - with clear explanations, their relevance to facility managers, and how they align with commercial chain operations.

EER – Energy Efficiency Ratio

- What it is: The ratio of cooling output (in BTU/hour) to electrical input (in watts), measured at a specific operating point - typically 95 °F outdoor, 80 °F indoor, 50% humidity.1

- Why it matters: Reflects “peak” cooling efficiency. Useful when outdoor temperatures climb high - common in many regions.

- For managers: When comparing equipment performance during extreme heat, EER offers a direct comparison point.

SEER – Seasonal Energy Efficiency Ratio

- What it is: Cooling output over an entire cooling season divided by energy consumed in Watt-hours. Essentially a weighted average of EER across varying outdoor temperatures (65 °F to 104 °F) and time bins.

- Why it matters: Captures average real-world efficiency across a season - not just peak conditions.

- For managers: SEER tells you how much energy the system will typically consume over time - great for budgeting and operational cost projections.

SEER2 – Seasonal Energy Efficiency Ratio 2

- What it is: As of January 1, 2023, the Department of Energy introduced SEER2 to replace SEER, using updated test procedures that better reflect real-world operating conditions, including higher external static pressures in ductwork.

- Why it matters: SEER2 values are always lower than SEER numbers for the same piece of equipment, not because the system is less efficient, but because the testing is more rigorous.

- For managers: When reviewing bids or proposals, confirm whether efficiency is listed as SEER or SEER2, and ask vendors for both if necessary. This ensures apples-to-apples comparisons and verifies compliance with new DOE minimums.

IEER – Integrated Energy Efficiency Ratio

- What it is: A more advanced rating that integrates performance at different load levels (25%, 50%, 75%, 100%) and varying outdoor temperatures, per AHRI Standard 340/360 (2015).2

- Why it matters: It’s the most realistic indicator of energy use throughout variable operating conditions - reflecting real commercial usage.

- For managers: IEER helps predict actual efficiency and costs across the year - not just in ideal or worst-case scenarios. Best for system-level comparisons.

HSPF – Heating Seasonal Performance Factor

- What it is: A metric for heat pump heating efficiency, defined as heating output (BTU) per electrical input (Watt-hours) over the heating season.

- Why it matters: Indicates year-round cost-effectiveness for heat pump-based systems.

- For managers: Important if your facilities use heat pumps: a higher HSPF means lower winter energy bills.1

HSPF2 – Heating Seasonal Performance Factor 2

- What it is: Like SEER2, HSPF2 was adopted in 2023 as an updated test method that accounts for more realistic external static pressures and new calculation methods.

- Why it matters: HSPF2 ratings will appear numerically lower than the older HSPF values for the same equipment, but the newer test gives a more accurate reflection of real-world performance.

- For managers: Be sure proposals specify whether they’re quoting HSPF or HSPF2. Rely on HSPF2 for compliance and budgeting moving forward.

AFUE – Annual Fuel Utilization Efficiency

- What it is: Relevant for gas furnaces - percentage of fuel converted into heat (vs. wasted). Expressed annually (e.g. 90% AFUE = 90% fuel to heat).

- Why it matters: High AFUE means less wasted fuel each year.

- For managers: Useful when evaluating heating systems fueled by natural gas or propane - linked to ENERGY STAR and ASHRAE criteria.

TSPR / COP – System Performance Metrics

- What it is: In ASHRAE 90.1’s Performance Rating Method (PRM), system-level efficiency metrics like Coefficient of Performance (COP), Integrated Part Load Value (IPLV), and Total System Performance Ratio (TSPR) are used to evaluate whole-system performance.3

- Why it matters: Especially relevant to designing, benchmarking, or certifying entire building systems.

- For managers: Use when participating in energy code compliance (e.g., ASHRAE 90.1 performance path) or benchmarking initiatives.

3. Why Efficiency Ratings Matter – From a Facility Manager’s View

Operational Cost Control: One of the clearest reasons efficiency ratings matter is their direct link to energy costs. A higher-rated system uses less electricity or fuel to achieve the same amount of heating or cooling, which translates to lower monthly utility bills. For example, upgrading from a SEER 9 system to SEER 13 reduces energy consumption by about 30%. Across a chain of stores or branches, even small percentage improvements per unit multiply into substantial cost savings annually. By paying attention to these ratings, you’re essentially managing operating expenses before the first energy bill arrives.

Lifecycle Value & Capital Planning: Efficiency ratings also factor into long-term equipment strategy. While high-efficiency systems usually carry a higher upfront price tag, they often deliver lower operating costs and faster payback periods. When scaled across multiple sites, choosing systems with better SEER2, IEER, or AFUE ratings can mean millions saved in energy over the equipment’s lifecycle. For facility managers tasked with capital planning, these ratings provide a concrete way to forecast ROI and justify investments to finance or corporate leadership.

Vendor & Chain Alignment: Consistency is another benefit. By setting minimum efficiency standards - say, IEER 14 or SEER2 15 - across all vendor contracts, you ensure that every new rooftop unit or split system installed across your portfolio performs to the same baseline. This standardization not only simplifies budgeting and performance tracking but also strengthens negotiating power with vendors who know your expectations upfront. Efficiency ratings become a tool to align multiple vendors under one consistent operational standard for the entire chain.

Regulatory & Sustainability Compliance: Efficiency ratings aren’t just about saving money; they’re also about staying compliant. Building codes, including ASHRAE 90.1, establish minimum efficiency levels for new installations, and many states and municipalities adopt these standards into law. Ratings like SEER2, IEER, and AFUE directly connect to whether or not a project will pass inspection. At the same time, corporate ESG and sustainability goals often require chain-wide improvements in energy performance. Knowing how ratings tie into code compliance and sustainability benchmarks helps you navigate both regulatory requirements and internal corporate reporting.

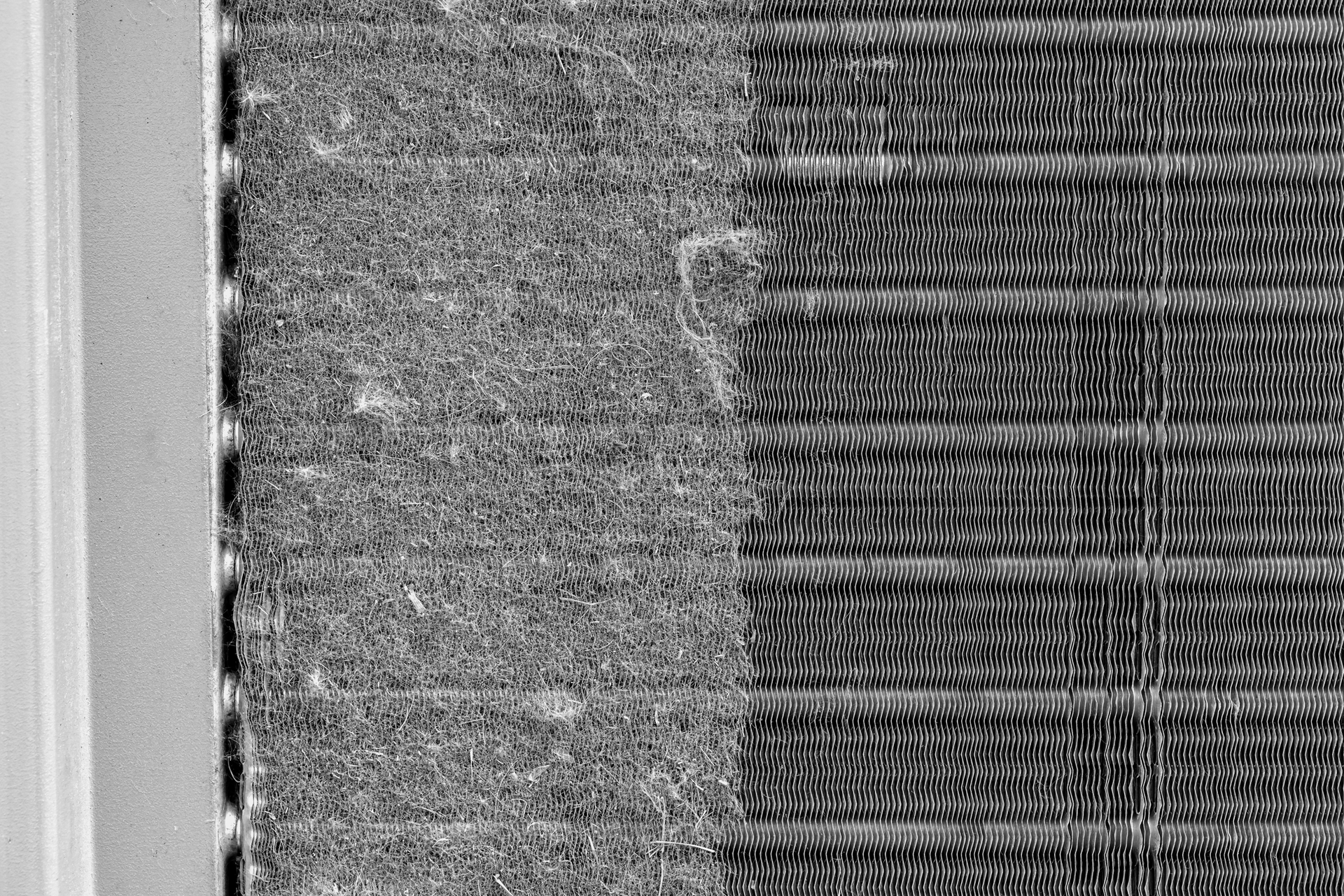

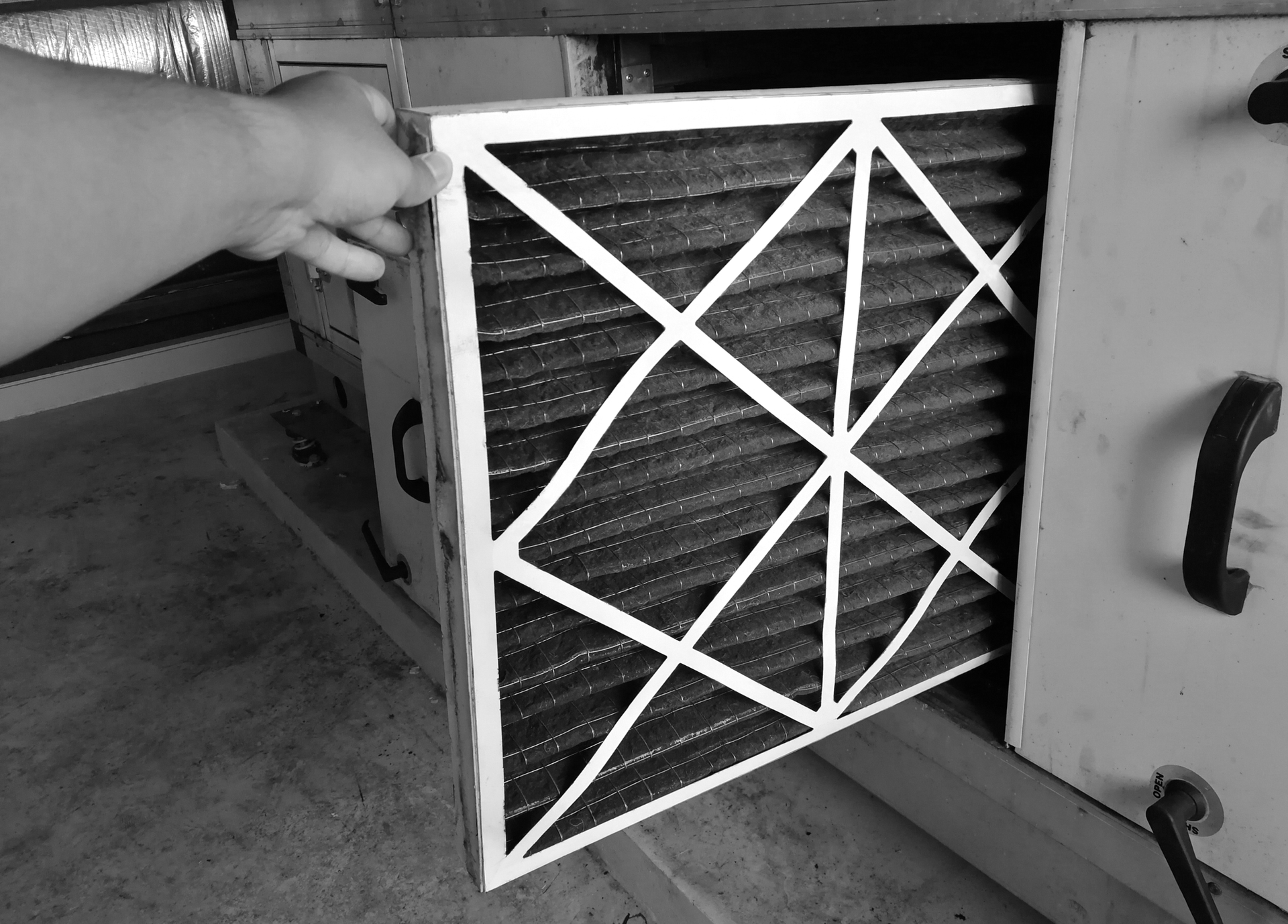

Maintenance & Degradation Monitoring: Finally, efficiency ratings serve as a benchmark for performance over time. Even the highest-rated unit won’t maintain its efficiency without proper upkeep. ASHRAE Standard 180 underscores the need for routine inspection and maintenance to preserve system efficiency and comfort delivery.4 By monitoring whether equipment continues to perform near its rated efficiency, facility managers can identify underperforming systems, justify proactive maintenance, or schedule timely replacements. In this way, ratings are not just purchase metrics but also ongoing tools to keep your chain’s HVAC portfolio operating at peak efficiency.

4. How to Use These Ratings in Your Management Role

| Task | Recommended Rating(s) | Purpose |

|---|---|---|

| Comparing equipment proposals | EER, SEER/SEER2, IEER, HSPF/HSPF2, AFUE | Understand energy performance under different scenarios. |

| Planning for peak demand management | EER | Helps prepare for utility peak charges during extreme heat. |

| Estimating seasonal energy costs | SEER2, IEER | Better reflects typical energy usage across chains. |

| Achieving code compliance | COP, IEER, AFUE, SEER2/HSPF2 | Required for ASHRAE 90.1 compliance. |

| Vendor contract standardization | IEER ≥ X, SEER2 ≥ Y | Ensures baseline efficiency across all installations. |

| Monitoring and maintenance | Compare actual vs rated efficiency | Detects degradation over time. |

| Budgeting & ROI analysis | Difference between ratings → Difference in energy use → cost savings | Provides justification for upgrades. |

5. Practical Example

Imagine your retail chain in a warm climate:

- One vendor proposes a rooftop unit with EER 12, SEER 16, SEER2 15, IEER 13.

- Another proposes EER 14, SEER 18, SEER2 16, IEER 15.

The second option costs more up front, but across 50 locations the efficiency gains translate into thousands of dollars in annual savings. Factoring in sustainability targets and code compliance, the higher SEER2/IEER equipment delivers stronger ROI and long-term value.

6. Summary & Manager’s Action Steps

- Know your acronyms: EER, SEER, SEER2, IEER, HSPF, HSPF2, AFUE, COP, IPLV, TSPR.

- Define standards in vendor contracts (e.g., IEER ≥ 14 and SEER2 ≥ 17).

- Track efficiency performance over time as part of ASHRAE-180 compliant maintenance programs.

- Align with ASHRAE 90.1 code requirements for new builds and retrofits.

- Model ROI and justify higher upfront costs with energy savings across your chain.

- Benchmark efficiency chain-wide to support sustainability and ESG goals.

Final Takeaway

Understanding and leveraging HVAC efficiency ratings isn’t just technical - it’s strategic. As a facility manager, these ratings are your tools to ensure comfort, comply with codes, control costs, and support sustainability across your entire chain.

Check out these articles we used as reference material:

1 Definitions and testing conditions for EER, SEER, HSPF: https://hvacdirect.com/info/understanding-hvac-efficiency-ratings-eer-hspf-and-seer.html

2 IEER overview and comparison with EER/SEER: https://learnmetrics.com/ieer-integrated-energy-efficiency-ratio/

3 ASHRAE 90.1 performance path metrics (COP, IPLV, TSPR): https://www.ashrae.org/file%20library/technical%20resources/bookstore/part6_90.1-2022mechanicalsystemperformance.pdf

4 ASHRAE Standard 180 for inspection & maintenance: https://www.ashrae.org/technical-resources/bookstore/standards-180-and-211

5 ASHRAE Energy benchmarking brief: https://www.ashrae.org/file%20library/about/government%20affairs/public%20policy%20resources/briefs/building-energy-benchmarking-and-performance-standards.pdf

Now that we've broken down the major HVAC efficiency ratings - we want to hear from you. Which one drives your decision-making the most? Have you run into challenges with HVAC efficiency ratings when working with vendors? Comment below - we’d love to hear your experience.